عنوان ماژول

توضیحات ماژول در این قسمت قرار میگیرد

Antibacterial

Antibacterial

Antibacterial B. P. Sharif Co. products, trade name of Polysharif®, is supplied to the market as Functional Polymeric Masterbatch Granules for the purpose of doing a function and duty in polymeric final products. One of the most useful masterbatch is Polysharif-antibacterial Masterbatch which can be employed in food packaging as trays and flexible films. The base of the masterbatch is low density polyethylene (LDPE) or polypropylene (PP). The antibacterial masterbatch is added during the melt processing of the final product in the range of 1 to 10 wt.%, depends on the application and type of the products. The antibacterial properties of the film and solid container can be evaluated according to ISO 22196:2011. According to the standards, the R-value for this product is about 2.5. It’s worth to state that the antibacterial properties is assigned when the R-value is greater than 2. The masterbatch is FDA approved and does not make any human skin sensitivity.

Specifications

Specifications Ease of processing for any blown and extruded film product

Without any change in processing parameters

R-value greater than 2

Low cost and affordability

Mechanisms

Mechanisms Destroying bacteria's outer membrane by nano-metal oxide particles and consequently killing the Bacteria

Applications

Applications Flexible Food Packaging (Bags, Films)

Solid Container (Tray and Bottles)

Toys

Household polymeric parts

Woven and non-woven textile

Plastic Pipe

Oxygen Block/ Scavenger

Oxygen Block/ Scavenger

Oxygen Block/ Scavenger B. P. Sharif Co. products, trade name of Polysharif®, is supplied to the market as Functional Polymeric Masterbatch Granules for the purpose of doing a function and duty in polymeric final products. One of the most useful masterbatch is Polysharif-O2Block Masterbatch which can be employed in food packaging as trays and flexible films. The base of the masterbatch is low density polyethylene (LDPE) or polyamide (PA). The O2block masterbatch is added during the melt processing of the final product in the range of 1 to 10 wt.%, depends on the application and type of the products. Utilizing this product, the oxygen transmission rate (OTR) of the polymeric film can be reduced dramatically. The OTR properties of the film and solid container can be evaluated according to ISO 15015-2:2003. According to the standards, the OTR value is less than 100 cc/m2 /24 hr. The masterbatch is FDA approved and contains clay nano-materials and Iron compounds.

Specifications

Specifications Ease of processing for any blown and extruded film products

Without any change in processing parameters

OTR less than 100 cc/m2 /24

Low cost and affordability

Mechanisms

Mechanisms The active (nano-) additives is incorporated into the polymeric matrix. In addition of active effect of the additives, they act like passive shield to inhibit gas permeability through the matrix.

Applications

Applications Oxygen scavenger bags and masterbatch granules can be provide for packaging of sensitive foods and beverage for shelf-life extension. For instance, the bottle lid can be an oxygen scavenger which can absorb trapped oxygen in head space as well as dissolved oxygen in liquid. Oxygen scavenger is also employed in bags, rigid containers and bottles.

Food packaging

Industrial packaging

Plastic pipe

Antifog

Antifog

Antifog B. P. Sharif Co. products, trade name of Polysharif®, is supplied to the market as Functional Polymeric Masterbatch Granules for the purpose of doing a function and duty in polymeric final products. One of the most useful masterbatch is Polysharif-antifog Masterbatch which can be employed in food packaging and green house films. The base of the masterbatch is low or high density polyethylene (PE) and polypropylene (PP). The antifog masterbatch is added during the melt processing of the final product in the range of 1 to 10 wt.%, depends on the application and type of the products. The antifog properties of the film can be induced immediately after the manufacturing process or a few hours after the process. It’s worth to state that the antifog properties caused by this masterbatch is permanent and can not be destroyed after mechanical abrasion of the products. The masterbatch is FDA approved and does not make any human skin sensitivity.

Specifications

Specifications Ease of processing for any blown and extruded film products

Without any change in processing parameters

Permanent antifog properties

Low cost and affordability

High efficiency, even in hot fog test

Can be used for HDPE and PP (surprisingly)

Mechanisms

Mechanisms The antifog agent/additive in polymeric films can enhance hydrophilic properties. It means that via incorporation of antifog agent into the polymeric matrix the water drop contact angle would be reduced and causes wet ability on polymer surface (Creating a very thin film of water on the polymer surface.

Applications

Applications For some packaging (food, fresh produce, readymade food, flower and etc) display of the packaged matter affected by fogging on the inside wall of packaging container. In fact, fogging can influence the

Anti-fog masterbatch Keeps food wrap films and other types of packaging transparent during cold storage and in places with changing temperatures Helps to avoid fogging from chilled and hot-packaged food Prevents the reduction of light transmission in packaging wall.

Food Packaging

Green house film

Ethylene Scavenger

Ethylene Scavenger

Ethylene Scavenger Ethylene is a gas released by some fresh produces that causes produce to ripen faster. Some Fresh Produces are more sensitive to ethylene than the others. Ethylene, also known as the ‘death or ripening hormone’ plays a role in many processes of plant growth, development and eventually spoilage. The Ethylene absorber masterbatch can be used 1 to 10 wt.% in food packaging production. The ethylene absorber inside the packaging wall can get the released ethylene gas trapped inside the packaging and inhibit fast spoilage of the fresh produces.

Specifications

Specifications Low cost

Without any changes in processing conditions

Acceptable opacity for shopping bags and food packaging

High efficiency

Mechanisms

Mechanisms Nano-porous particles incorporated into the polymer matrix. Ethylene gas produced by the calmative fresh produces can be adsorbed physically on the nano-particles. Indeed, there is capacity for adsorption which is calculated for each produce to determine the required ethylene absorbent masterbatch.

Applications

Applications Fresh Produces packaging for shelf-life extension

Odor adsorption for recycled products

Odor adsorption for garbage bags

Antiblock

Nano-particles

Antiblock

Antiblock When two or more layers of plastic stick together during production or storage, it can be a big challenge during manufacturing of polyethylene (PE) films.

Antiblock Additive masterbatch using nano-particles can solve this problem. By creating nano-roughness on the polymer surface sticking of the films is inhibited.

Specifications

Specifications Inorganic Nano-particle

Nano-roughness

Without opacity

Very Low concentrations

Mechanisms

Mechanisms Creating nano-roughness on the polymer surface

Applications

Applications LDPE films

LDPE bags

PP films and bags

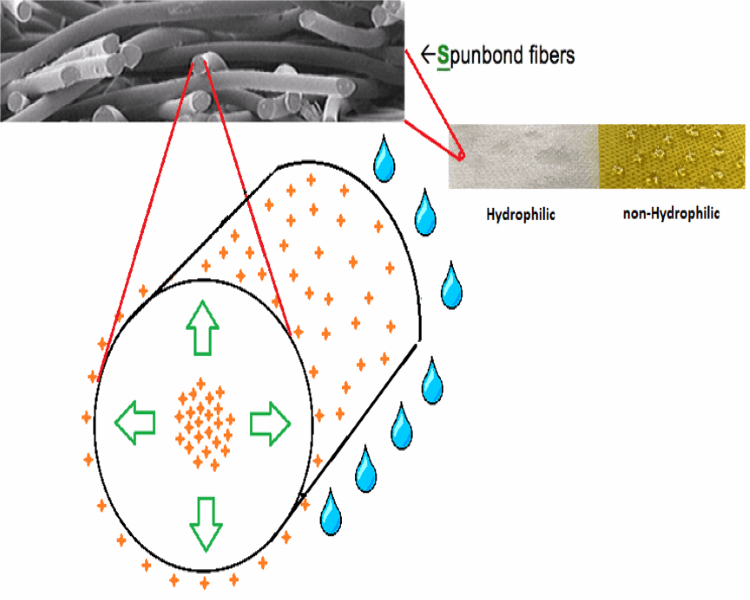

Hydrophilic

Hydrophilic

Hydrophilic Polypropylene (PP) fibers, widely utilized in nonwoven industry, have highly hydrophobic surface properties. Therefore, a modification in order to create a polar surface is an important issue where wettability and adhesion properties are required. PP has a very low value of the surface free energy and, consequently, has very weak hydrophilic properties. In many industrial applications there is a need to modify the polymer surface with keeping their desired unchanged bulk properties. Chemical treatment of the surfaces is the most often used method for inducing, hydrophilicity. In conventional methods, the produced nonwoven fabric will be impregnated via specific solution passing through a bath and subsequent drying and rolling. The hydrophilic properties induced by this method is temporary, costly and may make smell during water absorption. However, the economical-technical requirements, force the industry to search alternative efficient methods.

Our special way to impart surface hydrophilicity into polypropylene is blending of the melt additives during the fiber spinning process. In fact, the hydrophilic masterbatch, containing ologomeric additives, is added during the melt processing of the final product fabrics in the range of 10 to 15 wt.%, depends on the application and type of the products. The hydrophilic properties of the fabric can be induced immediately after the manufacturing process. According to our researches, oligomeric additives, spun with host polymer, migrate to surface and generate surface hydrophilicity at low concentration without altering bulk properties. The additives migrate to the surface gradually leading to a durable hydrophilic PP surface.

Specifications

Specifications PP Masterbatch, White

Processing methods Spun Bond, Blown Film

Uses Masterbatch, 10% w.t.

Processing Temperature 250 oC

Specific gravity ASTM D792 900-910 kg/m3

Additive content - 5 %

Melt Flow Rate ASTM 1238 25 g/min

Tm ISO 3146 165 oC

Excellent Water absorption

Soft feeling

Excellent strike through re-wet properties

Free from chemical agents

Soft on sensitive skin

Long duration

Without smell after water absorption

Lower cost in comparison to conventional methods

Polysharif® Hydrophil is packaged in 20 kg lined aluminum foil or in moisture barrier bags. Polysharif®Hydrophil should be stored in dry conditions.

Mechanisms

Mechanisms The surface energy and the polar contribution of the polypropylene film increased due to the migration of low-molecular-mass components (additives) to the surface resulting in increase in surface wettability. Our experiments reveals migration and surface enrichment of additives via concentration difference between the surface and the core of the fiber. In addition, a more hydrophilic surface will be made by increase in the surface amount of polar oxygen groups.

Applications

Applications Diaper (Baby and Adult)

Face wipes

Bed sheets (Hospitals, Railways, and Buses etc.)

Spa product

Medical Disposable

Masks

Transparent Filler

Nano-particles

Transparent Filler

Transparent Filler B P Sharif Company special transparent nano-Filler Masterbatch was created to make cheaper polymeric final products without any opacity. The transparency are very well applied into PE/PP/PS/ABS, which improve the transparency and brightening of the plastic. Nano transparent filler masterbatch can be loaded with 10-30% dosage which will not affect the virgin material transparency as well as mechanical properties.

High transparent nano-based filler masterbatch with good dispersion ability, easily used without any change of processing conditions. Interestingly, it can also improve mechanical properties of the final product.

Specifications

Specifications Low cost obtained by filler without any opacity

Without any changes in processing of polymer

Increasing mechanical properties

good dispersion of nano particle in polymeric matrix

Mechanisms

Mechanisms Making refractive index of polymer close to nano-sized inorganic particles.

Applications

Applications HDPE and LDPE shopping bags

PP Trays and sheets

PP fibers

Table Cover (single use)