عنوان ماژول

توضیحات ماژول در این قسمت قرار میگیرد

History Trend of Advanced Packaging

Vacuum Packaging

Vacuum Packaging  Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP)  Active Sachet

Active Sachet  Active Packaging (Controlled Atmosphere)

Active Packaging (Controlled Atmosphere) Technology

In general, during the time, different generations of the advanced food packaging technologies can be categorized as follow:

- Vacuum

- Modified Atmosphere Packaging (MAP)

- Active Sachet

- Active Packaging (AP) or Controlled Atmosphere (CA)

- Smart/ Intelligent Packaging (IP)

One of the main reasons for food spoilage is existence of the oxygen gas in vicinity of the food. Therefore, in Generation I, it had been tried to remove the oxygen gas from the packaging atmosphere via vacuum technology. The vacuum technology causes a significant improvement in fool shelf-life. The cons of the vacuum technology are: high cost, need of especial equipment, need of sealed packaging to inhibit vacuum drop. The modified atmosphere packaging (MAP) is the second generation of the food packaging. In this technology, inert gases or determined gas mixture is injected into the sealed packaging. Determined gas can extend shelf-life of the packaged food. Sealing of the packaging is the most important parameter in MAP technology. Since leaking can change the whole scenario. In addition, similar to vacuum technology, the MAP technology needs especial injection equipment as well as consumable gas, which can make practical and economical drawbacks. However, vacuum and MAP technologies are being utilized in food packaging industries. In 1976, the third generation of advanced food packaging has been introduced in market by Mitsubishi Chemical named Active Sachet. These sachets can absorb ethylene, oxygen as well as moisture to control the inside atmosphere of the packaging. The adsorbent material is put inside the sachet and then the sachet is put inside the packaging leading food and pharmaceutical products shelf-life extension. For the case of fresh produces, various adsorbent sachets should be employed to control other spoiling agents beside oxygen gas such as ethylene, CO2 and moisture. However, while this technology is successful in shelf-life extension and freshness improvement, existence of some cons restricts its usage. Local action of sachet and possible leakage of the adsorbent materials into the packaging is some those cons.

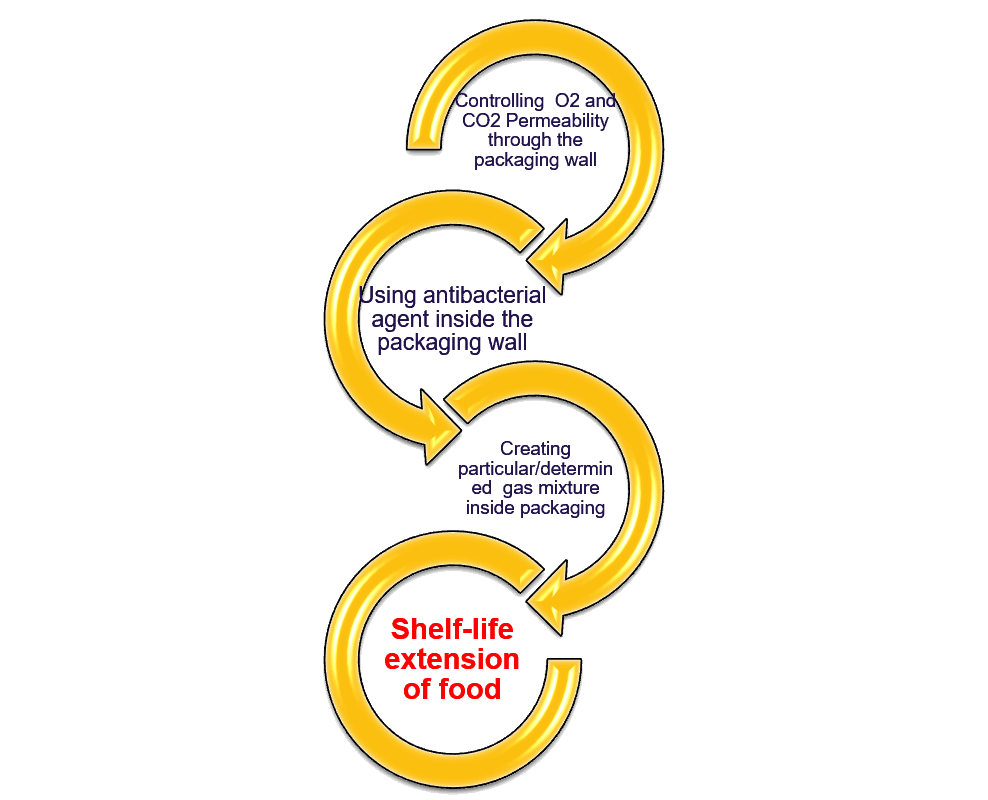

However, need for controlling other spoilage agents beside oxygen, leaded introduction of the fourth generation of food packaging named as active packaging or controlled atmosphere packaging. For the case of active packaging, the effective/active materials are incorporated into the polymeric wall of the packaging. The active materials can control the gas mixture inside the packaging via adsorption as well as gas transmission control through the packaging wall.

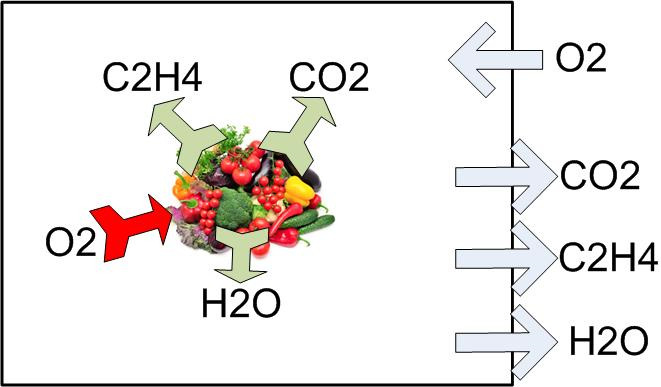

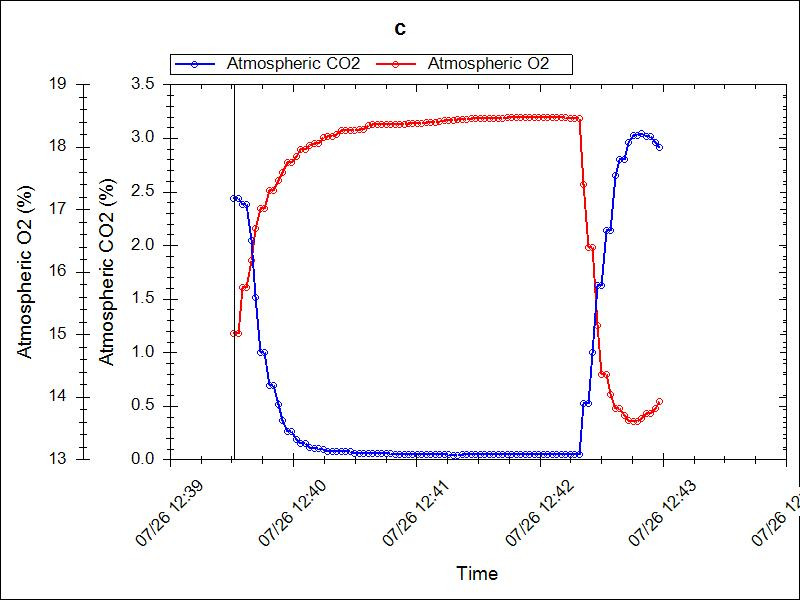

In addition of controlling of the atmosphere of the packaging, these packaging can be antimicrobial. Ease of application for active packaging make them competitive in comparison with other above mentioned previous technologies. The active packaging has succeeded in fresh produces packaging, i. e. fruits, vegetables, which breath after harvest. In fact, the fresh produces breathe like live human, that means, consume oxygen and give back CO2 and ethylene as well as moisture to the atmosphere called “respiration”. The respiration causes aging and spoil of the fresh produces. Existence of about 21 vol.% oxygen at beginning inside the packaging as well as permeability of the polymeric packaging for the gases makes the respiration of the fresh produces more complicated. In other words, the consumed trapped oxygen gas inside the packaging can be supplied from outside through the packaging wall continuously. Therefore, the respiration process and aging will keep going on till complete spoilage. In other side, each fresh produce needs its own especial gas mixture, i. e. O2/CO2/Ethylene, moisture, inside the packaging to have its maximum shelf-life. These conditions makes preservation of the fresh produces more complicated during transport for export and storage time.

In summary, Oxygen causes oxidation and promotes the enzymatic and non-enzymatic phenolic browning of fresh fruit and the growth of microorganisms. Packaging without or with less extends shelf-life and inhibits deterioration. CO2 gas is one the by-products during respiration of fresh produce. This gas provides a condition for growth of anaerobic mico-organism inside the packaging. The CO2 gas should be taken out of packaging through the packaging wall. However, for some cases, high level existence of CO2 gas inside packaging can extend shelf-life of packaged food. Therefore, the CO2 gas should be kept inside the packaging. Depending on the food product, a high or even a low level of moisture can stabilize the product quality and enhance the shelf life. An adequate choice of packaging material and barrier properties regulates the moisture level and supports the end product quality. The moisture vapor transmission rate (MVTR) of the packaging materials, i. e. polymeric materials, is the most important factor and has to fit with the moisture requirements of the food. The critical moisture content is a useful parameter to ensure product quality. However, once a certain critical amount of moisture is present, changes to the taste or smell can be detected that could make the product un-saleable (but not unhygienic). For example, some biscuits can absorb 2% more moisture than that present when they are freshly baked and the consumer would not be able to detect a difference. However, above this moisture level a distinct lowering of quality and a loss of crispness would be noticed.

As mentioned, for the active packaging, the active (nano-) additives is incorporated into the polymeric packaging wall. In addition of active effect of the additives, they act like passive shield to inhibit gas permeability through the packaging wall. Therefore, shelf-life extension is made by two mechanisms, i. e. passive and active. It should be considered that each agricultural commodities and food type must be packaged in a certain packaging bags/container. Utilizing functional active polymers in various industries is expected to grow significantly. As come up from its name, it is expected that a specific function to be done in the final products. This specific function can be: oxygen scavengering, ethylene absorbing, UV absorbing, CO2 emitting, moisture controlling, antmicrobial, super hydrophilicity, super hydropholbity and etc.

In fact, an interaction is made between the packaged food and the packaging polymeric wall. Food quality improvement and freshness enhancement is the consequence of active packaging usage. Therefore, shelf-life extension and food waste reduction is obtained via using active packaging.